Hotmelt.com is please to announce the Foundry TEC hot melts from Power Adhesives. Foundry TEC hot melt is perfect for most foundry systems with benefits such as, instant bonding with a short or no wait time, improved accuracy, increased productivity and a reduction in scrap. Foundry TEC comes in both 1/2" glue sticks and 1 3/4" glue slugs, perfect for using with the TEC 820, TEC 3400 and TEC 6100 glue guns.

The Foundry TEC hot melt works extremely well when a cold processes are used like 'cold box', 'alpha set' and 'beta set'. Not only can they be used during the cold process but also works with 'warm box', 'hot box' and 'shell'. Power Adhesives has 5 hot melt adhesive formulas designed specifically for different foundry processes.

Foundry TEC Hot Melt Formulas

- General Purpose Sand Core Hot Melt

- Long Open Time Sand Core Hot Melt

- Polyamide Sand Core Hot Melt

- Low Ash Content Sand Core Hot Melt

- Fast Setting Sand Core Hot Melt

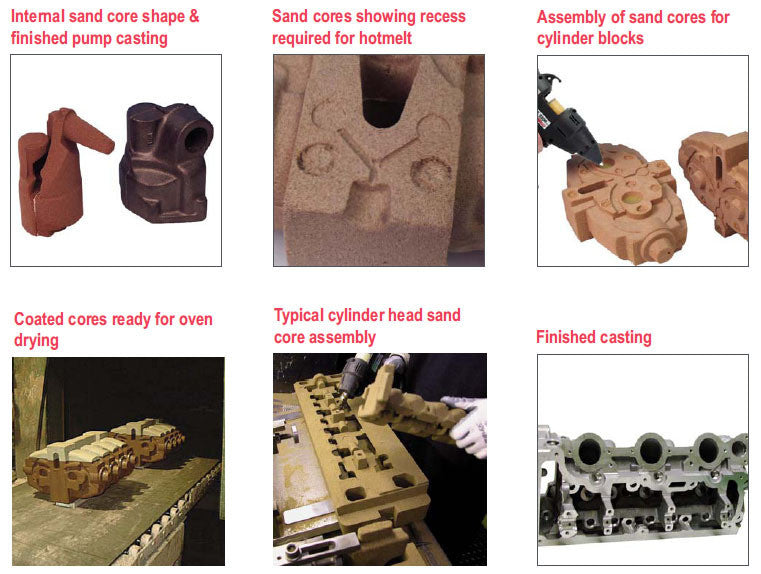

Easily make some small adjustments in tooling to create the required recess in the sand cores needed for using hot melt. The high temperatures of of the drying ovens are no problem for Foundry TEC hot melt. The insulation of the sand and the high temperature hot melt allow the Foundry TEC to resist high oven temperatures. Between the insulation properties of the sand combined with the fast setting time of the metal and physical fit of the core maintain the integrity of the sand core long enough for the metal to solidify correctly from the sand core.

For larger assemblies foundries can use both water-based adhesives and hot melt. The hot melt acts as a instant bond which allow for the cores to be dipped immediately in a water-based adhesive to give them very high temperature resistance. Foundry TEC hot melt adhesives do not affect sand reclamation.

If you have any questions regarding Power Adhesives Foundry TEC hot melt adhesives please give us a call 877-933-3343 or contact us here.