Adhesives for Vinyl

Vinyl, also known as polyvinyl chloride (PVC), is a synthetic plastic containing chlorine, ethylene, and various other additives depending on the desired properties. There is rigid PVC, plasticized PVC, and many other grades. It is an incredibly versatile plastic that is used in everything from vinyl flooring to interior car moldings.

While the plastic has a diverse number of applications, there are some challenges with gluing polyvinyl chloride. First of all, vinyl has a lower surface energy that many adhesives struggle to adhere to. Secondly, some hot glues could damage the plastic and cause it to melt. Fortunately, there are some specialty hot melt adhesives for vinyl that are able to create strong bonds.

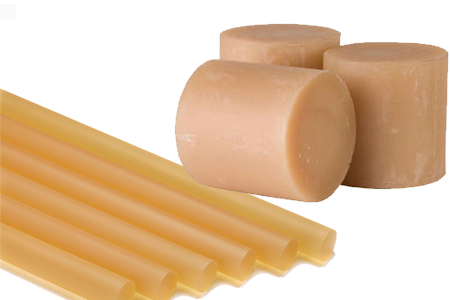

Hot Melt Adhesives for Vinyl

-

![Infinity PUR MP75 10 ounce Cartridge with Disposable Nozzles]()

Infinity PUR MP75

A best-selling adhesive for bonding PVC as well as many other materials, this product has waterproof properties that make it suitable for a wide range of applications. It also has a longer set time compared to many PURs and is applied at 250 degrees Fahrenheit.

-

![Infinity Bond Awesome Acrylic]()

Infinity Awesome Acrylic Hot Melt Glue Sticks

Another best-selling adhesive, these ½ inch glue sticks are different from traditional hot glue sticks. They can form strong, flexible bonds with vinyl plastic that can hold up in low temperatures and in demanding environments. They will also dry almost completely clear for a better-looking finished product.

-

![Surebonder 925 Hot Melt Glue Sticks]()

Surebonder 925 Glue Sticks

These ½ inch glue sticks were originally designed to bond carpet tack strips to cement, but their applications are now numerous. They have a working time or 60 to 80 seconds and a softening point of 165 degrees Fahrenheit. On top of this, they are FDA approved for food packaging.

Using Hot Melt Adhesives to Bond Vinyl

Hot melt adhesives are a type of polymer-based adhesive without any water or solvents. They are solid at room temperature, melted before application, and then will harden as they cure. They also have a fast set speed, are often moisture resistant, and can be altered to have different properties.

Hot melts are great for many reasons, but they are not always the best adhesive for vinyl and other plastics. Some could damage the plastic or may not be able to adhere well enough to form a strong bond. While there are some structural adhesives for plastic, a hot melt may be a better choice depending on the application. Before choosing a vinyl hot melt glue, it is important to look at the product's technical datasheet as it should list the different types of substrates that it can bond as exact bonding capabilities vary by product.

When using hot melt glue on vinyl, it is also important to do proper surface preparation in order to get the best results. Surface preparation for vinyl will typically involve cleaning, abrading, and priming the surface as needed. Most products will come with specific surface preparation instructions as well as instructions for application. Since set times can vary greatly from one hot melt to another, it is important to also keep this in mind when choosing a hot glue for vinyl.

Let Us Help You

Finding the right hot melt adhesive for plastic applications can be a challenge, but we want to help. As experts in the industry, we have the experience needed to point you in the right direction and find you the right hot melt adhesive for vinyl plastic. Reach out to speak with one of our team members and get a personalized product recommendation for your application.

Adhesives for Leather

Ask a Question

Have questions? Our team of adhesive experts can help. Submit your questions and we'll get you answers right away. We're here to help.