Updated March 12, 2025

Businesses and industries all over the world use hot melt equipment to speed up and simplify the packaging process. From sealing cartons to binding books, hot melt machinery can offer a more efficient and less wasteful process to get products into consumers' hands.

But like with any major piece of equipment, these machines need some TLC to perform at their optimal level. We not only take a closer look at the importance of cleaning hot melt equipment but also how to clean your hot melt tank and give some recommendations on what products you can use.

Why It's Important to Clean Your Adhesive Melter

Removing residual hot melt from your equipment is crucial for several reasons. Not only does it ensure that the equipment operates efficiently, but it can also extend the lifespan of your hot melt adhesive system. Over time, hot melt nozzles, hot melt hoses, tanks, and conveyor belts can all get clogged with residue from the adhesives they dispense. When the residue burns and becomes solid, it is known as adhesive charring.

This buildup can lead to several problems including:

-

Uneven adhesive application

-

Product defects

-

Higher reject rates

-

Increased downtime

-

Premature wear and tear

-

Costly repairs or parts replacements

-

The release of toxic fumes

Conversely, regular maintenance and cleaning of hot melt systems can improve efficiency, increase the service life of the equipment, minimize unnecessary downtime, improve safety, and reduce overall costs.

How to Clean Your Hot Melt Tank

Every hot melt equipment manufacturer has different guidelines on how their equipment should be serviced as well as how often. Most manufacturers recommend a complete hot melt system cleaning twice a year to ensure the service life of the equipment. Along with the equipment itself, exactly how you clean your hot melt glue machine will also depend on the products you use. Always follow the manufacturer's specific instructions to ensure best results.

While the process can vary, we share some general instructions on how to clean hot melt equipment.

How to use a hot melt surface cleaner:

-

Turn off the machine and unplug it from the power source.

-

Allow the system to cool down completely.

-

Remove any excess adhesive from the machine using a scraper or putty knife.

-

Spray the cleaner directly onto the adhesive residue and let it sit for the recommended amount of time.

-

Wipe the residue away with a clean cloth.

-

Repeat steps 4 and 5 as needed until all residue is removed.

-

Clean the hot melt machine with a damp cloth to remove any remaining cleaner.

-

Allow the machine to dry completely before using it again.

How to use a purge cleaning solution:

-

Pour the cleaner into the hot melt adhesive system's tank.

-

Set the temperature according to the manufacturer's instructions.

-

Let it circulate through your machine until the reservoir is clean.

-

Drain your hot melt dispensing system.

-

Scrape away any remaining char.

-

Discard the first few minutes of adhesive from your tank.

Cleaning Products to Try

There are several different hot melt cleaners available, so it can be hard to know what to choose. Our team of adhesive experts is sharing some popular products you may want to try.

Henkel Technomelt® Melt-O-Clean Cleaner

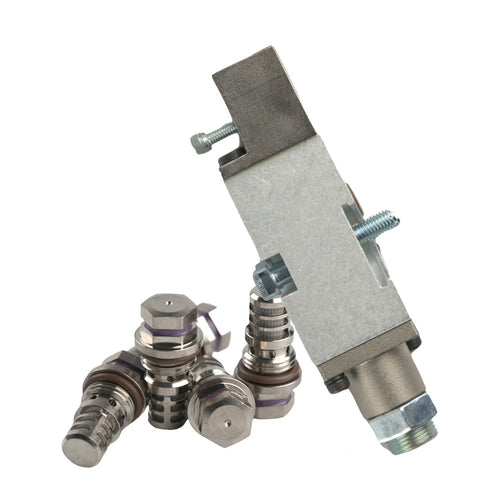

A popular solution to clean hot melt glue tanks, this product is a cold cleaning agent that should be applied at room temperature. It's specially formulated to remove residual adhesives, grease, and grime from nozzles and machine parts. It is non-toxic, made from organic materials, and has a citrus smell.

Infinity Bond EnviroClean Hot Melt Cleaner

This surface cleaner is a cold cleaning agent that can clean hot melt unit surfaces to remove not only residual adhesive but also heavy grease and grime. It is non-toxic and does not need to be mixed with another solution. EnviroClean also won over our experts for its value and cost-savings compared to some other cleaners.

Infinity Bond Environflush Hot Melt Cleaner

For those looking for more than just a surface cleaner, we suggest trying this product. It is a cleaning solution used for purging hot melt adhesive systems. Like EnviroClean, Enviroflush is specially formulated to remove hot melt residue from machinery and equipment without causing any damage. It is biodegradable, non-toxic, and requires no mixing to use.

This product is great for cleaning and flushing out tanks, hoses, and applicators without any additional equipment required. When used during routine maintenance, it helps remove char, residue, and buildup to extend the lifespan of your machine.

Need Help?

We understand that cleaning your hot melt adhesive system can feel like quite the undertaking. Regular cleanings and purges are vital to keep the system serviceable and avoid the wasted time, money, and headaches that come with disruptions.

While this guide may have been able to cover the basics of cleaning hot melt systems, we know that every system is different, and the devil may be in the details. To help, we offer a hot melt equipment maintenance program to do the work for you. With our industry knowledge, tools, and spare parts, we can carry out maintenance, repairs, and cleaning of hot melt equipment in a fast and efficient manner.

Other helpful services we have to offer include:

-

A full catalog of hot melt parts for purchase.

-

New or refurbished hot melt systems for purchase.

-

The potential for free equipment with your adhesive purchase. Learn more.