February 13, 2025

Hot melt can be used in various applications including packaging, product assembly, automotive, and more. Unfortunately, air can become trapped in the hot melt at various times throughout the application process, especially when using bulk hot melt.

Although it is a common occurrence, it can become a big issue. Air bubbles in hot melt adhesives may negatively impact bond strength and adhesion. In the end, these issues can lead to a faulty finished product, packaging pop-opens, or an unsightly final look.

Common Causes of Air Pockets in Hot Melt

Several factors can lead to the formation of air bubbles in hot melt glue whether it is in the hot melt tank itself or after it is applied to the substrate. Our team of adhesive experts is reviewing some of the most common causes of air bubbles in hot melt adhesives.

-

Moisture on the Substrate- If the substrate has moisture on it before the hot melt is applied, it may lead to steam that will get trapped in the dried adhesive in the form of air bubbles.

-

Empty Melt Tank- If the tank is empty, it can lead to air bubbles in the system.

-

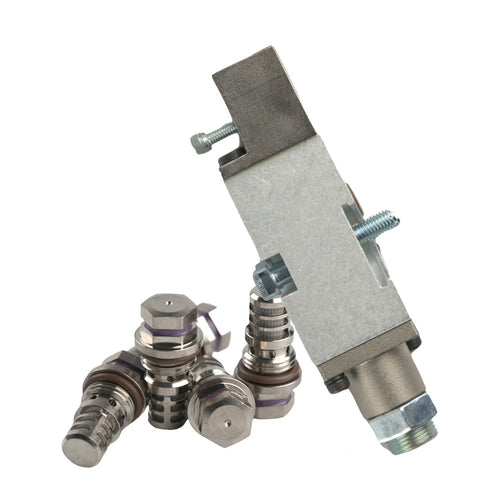

Damaged or Opened Purge Valve- A broken or opened purge valve can lead to air leaking into the system and the formation of bubbles in the hot melt adhesive.

-

Air Leaking into the Pump- When air gets into the pump, air bubbles can form in the adhesive.

-

The Adhesive Is Too Viscous- High-viscosity adhesives are more prone to air bubbles because their resistance to flow doesn't allow enough time for the air to escape.

-

Adhesive Supply or Melt Rate Exceeded- If the hot melt adhesive is overheated and melting too quickly, it may lead to bubbles forming.

How to Get Rid of Air Bubbles in Hot Glue

While bubbles are common, there are ways to minimize and prevent air bubbles in hot melt adhesives. Our team of adhesives experts is sharing some solutions.

-

Drying the Substrate- Part of proper surface preparation is letting the substrate completely dry before applying the hot melt. You will also want to make sure you manage the substrate storage humidity. Doing so can eliminate steam buildup and air pockets.

-

Fill the Tank- If the cause of the glue air bubbles is from an empty tank, you should fill the tank and operate the guns until the bubbles disappear.

-

Close or Replace the Purge Valve- If you suspect the air is coming from the purge valve, you want to first make sure it is closed. If that does not work, it may be defective and need replacing. See our selection of hot melt valves.

-

Replace the Pump or Pump Seals- If air is leaking into the pump, you will likely need to replace the pump seals or the pump itself. See our selection of hot melt pumps.

-

Decrease the Viscosity of the Adhesive- Air bubbles can get trapped in high-viscosity adhesives. Start by increasing the temperature by 10 degrees (within the acceptable temperature range for the adhesive) until the issue is solved. If this doesn't work, you may need a different adhesive altogether.

-

Increase the Supply of Molten Adhesive- When the adhesive is overheated and exceeds its melt rate, bubbles may occur. Increase the temperature per wattage, use a pre-melter, or choose a different adhesive with a higher melt rate.

Need More Help?

While common, air bubbles in hot melt adhesives can lead to a variety of issues. When you understand the causes as well as how to avoid air bubbles in hot glue, you can save your business a lot of wasted time and money.

If you are not sure what the problem is or you have yet to find the right solution, we want to help. Whether you need a hot melt replacement part or help choosing a new adhesive, we are here. Contact us to speak with one of our adhesive experts or to learn more about our hot melt equipment maintenance program.