There are a lot of adhesives on the market. Many are similar in their properties and designed for the same application, so how do you know which adhesive to choose?

At Hotmelt.com, we are powered by APPLIED Adhesives and have access to three testing laboratories including one with an ISO 9001:2015 certification. Consequently, we had a lab technician take a look at two similar adhesives to compare their abilities and help a company decide which product to use.

The first product was Jowat 259.20, an EVA hot melt with a low viscosity. The second was the ASURE CC6070 packaging adhesive, another EVA hot melt that is made for various applications. Our lab technician took a closer look at their bond capabilities as well as their thermal stability and compared the two.

Bonding Test

Setup

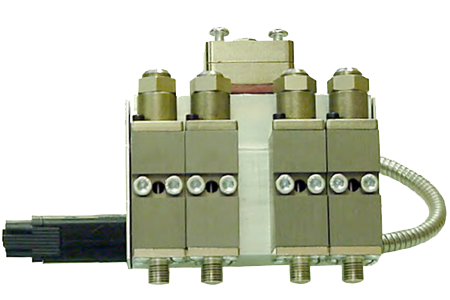

To test the bonding capabilities of Jowat 259.20 versus ASURE CC6070, our lab technician began by applying the adhesives to the same brown corrugated case material. Each was done in a typical application pattern with the use of a Graco Invispac HM10 glue melter at 350°F (the recommended application temperature).

Next, a second sample of the substrate was placed over the adhesive bead after one to two seconds of open time. It was then given two to three seconds of compression. These samples were tested immediately as well as after sitting for 24 hours in a room that was 72°F.

Results

Upon inspection of all the samples, both the Jowat 259.20 hot melt adhesive and the ASURE CC6070 adhesive showed excellent adhesion with deep, destructive fiber tear for both instances. Based on these results, the two appeared to have similar bonding capabilities.

Thermal Stability Test

Setup

During this time, a thermal stability test to compare the Jowat 259.20 hot melt and the ASURE CC6070 hot melt adhesive was also done. For this test, our lab technician followed the American Society of Test Methods (ASTM) D4499 standards.

The adhesives were added to separate glass jars. Initial measurements regarding a variety of factors such as color, viscosity, phase separation, and more were recorded. Next, the actual test began with the glass jars cooked in an oven at 350°F for 72 hours. The 72 hours is meant to mimic hot melt equipment being left on over the weekend without any production. After this time, both the Jowat 259.20 adhesive and the ASURE CC6070 adhesive were reevaluated for the same properties as before the test began.

Results

After the 72 hours had passed, our lab technician recorded a variety of changes in the adhesives as well as some properties that stayed the same. There were also some important distinctions found between the two adhesives. Detailed results can be found in the table below.

The Jowat 259.20 hot melt adhesive started out as a 7 on the Gardner color scale (dark yellow) and jumped up to an 11 (brown) after 72 hours of heat. In contrast, the ASURE CC6070 glue started at a 3 (pale yellow) but only made it up to a 9 (light brown).

Another noticeable difference between the Jowatherm 282.20 and ASURE CC6070 hot melt adhesive was their changes in viscosity. The Jowat 259.20 adhesive had an initial viscosity of 970 cps that increased by 24.23% to 1205 cps after 72 hours of heating. On the other hand, the ASURE product actually decreased in viscosity by 2.65% from 1130 cps to 1100 cps. There were also some differences in clarity and odor. Based on all these parameters, the ASURE CC6070 demonstrated superior thermal stability compared to the Jowat 259.20 glue.

Our Conclusion

Based on the results of both tests, we found that the ASURE product may be the better choice. While the adhesion was comparable, the thermal stability was a big differentiating factor between the two products.

Thermal stability of a hot melt refers to the pot life or its ability to resist breaking down from heat and time, including showing signs of adhesive charring or viscosity changes. Good thermal stability is especially important for applications where exposure to higher temperatures is likely. In this particular case, our lab technician was examining a closer look at how the adhesives would react to being left in equipment without use over a weekend.

On top of the thermal stability, these tests were initially performed because a customer had a request to find a cost-saving option for the Jowat 259.20 hot melt adhesive they were already using. The ASURE CC6070 product is not only a lower cost but also has good cost-efficiency by allowing SKU consolidation and supply chain streamlining.

Overall, the ASURE CC6070 hot melt adhesive is a water white EVA designed for case and carton sealing in particular, but it can be used in a wide range of packaging applications. Along with having excellent thermal stability, the ASURE CC6070 glue also has a long open time and set speed. Made for multiple uses, it is a highly versatile product that can have many applications.

Of course, every application is different, so it is important to test the adhesive on your substrate and in your bonding environment to see that it is a good fit for your application. We also offer adhesive lab testing as a service to do this for you.

Time to Switch?

If you are currently a user of the Jowat 259.20 adhesive, it may be time to look at ASURE CC6070 as an alternative. The high thermal stability and lower cost could be a game changer for your business. You can purchase a 30-lb sample case of ASURE CC6070 to test on your production line.

You can also contact us if you have more questions or need a product recommendation. We carry a large collection of ASURE hot melts and other adhesives with various capabilities.