New to hot melt? That's perfect, we all start somewhere. Let us shine a little light on what hot melt is, how it is commonly used and dispensed as well as some ideas for best practices.

What is hot melt?

Hot melt or hot glue consists of thermoplastic polymers that when melted, apply as a liquid but become a solid again as they cool. Hot glue is used in both commercial and residential areas. It is used for a variety of things such as crafts, hobbies, woodworking, assembly, packaging, labeling, etc.

A Little History

Hot glue was invented around 1940 by Paul Cope a Chemical & Packaging Engineer for Procter & Gamble. He invented it as an improvement to water-based adhesives that were failing in humid climates.

Benefits of Hot Melt

- Cost effective

- Easy to use

- Formulas made for a variety of applications/materials

- Easy to store

- Excellent seal quality

- Not messy

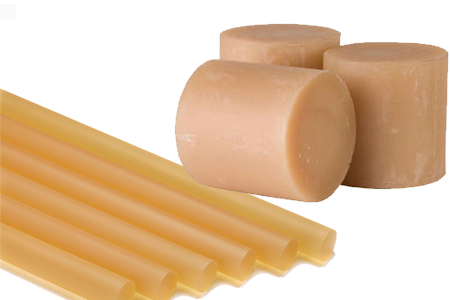

Different Types

There are a few different types of hot melt glue. Each has their own benefits and drawbacks.

EVA (Ethylene Vinyl Acetate) This polymer is suitable for both packaging and assembly formulas. It is economical and effective at service temperatures from -22 to 176 degrees F (-30 to 80 degrees C) Standard hot melt. EVA is the most common type of hot melt and used in applications like packaging and product assembly.

PA (Polyamide) This polymer used to formulate adhesives to create a better resistant to temperature extremes and chemicals -76 to 266 degrees F(-60 to 130 C).

Polyamide is an expensive product that offers high heat resistance compared to traditional EVA products.

PP (Polypropylene) This polymer often used in spray formulations, to create specific adhesion properties like delayed setting time it's effective at -22 to 230 degrees F(-30 to 110 C).

PUR (Polyurethane) Similar to the traditional hot melt, except after it solidifies PUR absorbs small amounts of moisture. The intake of moisture creates a permanent chemical change after several days. This chemical change increases both heat and chemical resistance of this adhesive. The chemical reaction allows the PUR to form a structure bond similar to that of epoxies, but in less time. PUR is perfect for numerous applications, but is commonly used in woodworking.

How much glue do I need?

Terms Associated with Hot Melt:

- Open Time - is the period available to make a bond.

- Viscosity - is the measure of resistance of a liquid. One of the most important qualities of hot melt as it influences the spread of the adhesive.

- Heat Resistance - the temperature at which the hot melt retains its physical appearance.

What is hot melt open time?

Hot melt open time is a term referring to the amount of time a user has after applying hot melt glue before the product sets up. Short open time hot melt adhesives are used in applications like packaging and product assembly. Long open time hot melts are used in spray applications or when bonding large surfaces where more time is required to apply and compress your substrates.

Shop our awesome selection of bulk hot melt from industry-leading manufacturers all at guaranteed low prices. You can also contact us for questions, samples or bulk pricing.