Updated July 30, 2024

About Polyurethane

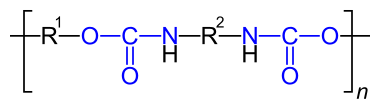

Polyurethane, or PUR, is a synthetic material made up of many organic units connected by urethane links. It is classified as a polymer because it has a molecular structure made up of similar units in a repeating chain.

Invented in the 1930s, PUR was first used as a cheaper alternative to costly rubber during World War II. Over time, other PUR applications were developed. Today, PUR has numerous applications including everything from airplane finishes to insulation and adhesives.

Characteristics of PUR Hot Melts

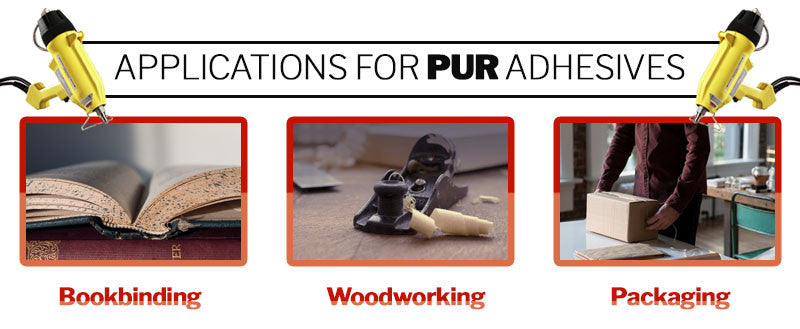

PUR hot melts are a relatively recent development. Introduced in the 1990s, these adhesives are often used in packaging, woodworking, and bookbinding. They are highly flexible and can withstand a broad range of thermal settings, making them ideal for hard-to-bind substrates.

Strength

When you compare traditional hot melts and PUR hot melts, you will notice that PURs are significantly stronger. They can provide adhesive strengths greater than 1,000 lbs. This higher strength is because PUR polymerizes when it comes into contact with the moisture in the air, so it forms stronger bonds after the curing process is complete.

In edge splice tests performed on composite wood panels by 3M, the wood substrate fractured under pressure while the PUR bond line stayed intact. This proved the superiority in the strength of PURs.

Volatile Organic Compound Content

Another characteristic of PUR hot melts is their low volatile organic compound (VOC) content compared to traditional hot melt adhesives. Since many VOCs are hazardous air pollutants, a low VOC count makes PURs the environmentally friendlier option. With PUR products, there also is no need to have drying and ventilation equipment on site after the adhesive is applied.

Set & Cure Times

Some PUR hot melt adhesives have fast set times and can form strong initial bonds in as little as 15 seconds. Most PUR adhesives also require 24 hours before they are completely cured, and during this time their strength continues to increase from reactions with the moisture in the air. This means it is very important to expose the PUR adhesive to air once it is applied.

Other Properties

In some cases, some products can be formulated with unique capabilities and specifications. Some other special properties for polyurethane hot melts may include higher levels of flexibility, better application temperature heat stability, thicker glue lines, thinner glue lines, and more. Some cartridges are even equipped with a UV indicator for quality control and to ensure that the adhesive has not been compromised before use.

Common Applications

Because of their many unique properties, PUR adhesives are ideal for working with difficult substrates that require some degree of elasticity. This unique property leads to many different applications for PUR hot melts.

Bookbinding

One application is bookbinding. The reason PUR is a great glue for bookbinding is that it eliminates any initial fixturing of the pages. The PUR also increases the book’s pull and flex strength, so books are more durable and can lie flat without the spine wrinkling. As a result, readers can bend the pages without breaking apart the spine.

Woodworking

Because of their unique characteristics, PUR hot melts are an excellent choice for a woodworking adhesive for wood furniture, decorative molding, edge-to-end grain wood adhesion, countertop edging, and more. They provide the high strength required to hold the materials together while also often providing a more aesthetically pleasing finished product by eliminating the need for screws and nails.

Because of their unique characteristics, PUR hot melts are an excellent choice for a woodworking adhesive for wood furniture, decorative molding, edge-to-end grain wood adhesion, countertop edging, and more. They provide the high strength required to hold the materials together while also often providing a more aesthetically pleasing finished product by eliminating the need for screws and nails.

Packaging

Just like EVA hot melts, PURs are an excellent choice for carton closing, sealing, and pallet stabilization, but PURs offer a stronger adhesion and cure better than traditional hot melts. Additionally, PUR adhesives are available in clear versions, so it is easy to hide glue lines and give an appearance of continuity in the material.

Working with PUR Adhesives

Due to the special properties of PUR adhesives, care should be taken when using and storing them.

Shelf Life

You can prolong the shelf life of PUR adhesives by storing them in a foil pouch in a cool, dry location. Because one of the main properties of polyurethane hot melts is that they react with moisture in the air to cure, take special care not to expose any tubes to moisture prematurely.

At the end of your workday, extrude a 1-inch bead of adhesive to ensure all the air has been extracted from the tube, effectively keeping it preserved. You can also use a PUR hot melt purge cleaner to prevent the PUR from hardening inside the nozzle. Most cartridges also provide detailed instructions on how to properly store the product inside.

Safety

When working with PUR hot melts, always make sure you have on personal protective equipment like gloves and safety glasses. You do not want the glue to come into contact with your skin or eyes as their rapid setting times make them difficult to get off. Additionally, you should never touch the applicator’s heat cylinder or cartridge when you are working.

Test Area

Whether you’re using PUR or another type of adhesive, you should always test the adhesive before the start of any project. First apply it on a small, inconspicuous area and wait for it to cure completely before applying it to the entirety of your project. You can do this on a scrap piece of material or apply the adhesive to a portion of your project that’s well-concealed.

Choosing the Right Product

Although the properties of PUR adhesives are similar, there are still many other factors to consider. You will want to think about material, temperature, curing time, set time, viscosity, cost, and more when you go to select a product for your job.

Temperature & Materials

The application temperature you use will depend on the materials you are bonding. You can use higher application temperatures for most projects involving wood, metal, and heavy cardboard because they are hardy and can withstand higher temperatures. The Infinity Bond superPUR 180 has a dispensing temperature of 250 degrees Fahrenheit and works well with wood, plastics, and metal.

For more delicate materials such as fabrics, foam, and paper, you will want to choose a product with a lower application temperature to avoid damaging the material. The 3M TE200 can be applied at a lower temperature to bond more delicate materials.

Check out our helpful High Temp Hot Melt vs. Low Temp Hot Melt guide to learn more.

Set Time & Cure Time

Set Time & Cure Time

Set time is the time required for the hot melt to become rigid and gain partial strength. It is different from curing time which is how long it takes for the hot melt to become completely dry and obtain its full strength. Most PURs have a longer curing time than other types of hot melts, but they make up for their longer curing time with faster setting times.

The Infinity PUR MP75 has a set time of three to four and a half minutes that allows for more manipulation during application. On the other hand, the 3M EZ 250015 only has a set time of 15 seconds and an open time of 90 seconds.

Viscosity

Viscosity is the resistance of a fluid to flow through a certain orifice. It is measured in pascal seconds or centipoise (cps for short). In this case, the orifice from which flow is measured is typically the applicator or the hot melt nozzle.

Hot melts can be described as having low, medium, or high viscosity. Fluids with low viscosity are thinner with a faster flow rate than fluids with high viscosities. You will want a higher viscosity product for projects where gap-fillings or assembly are involved. In packaging, using a thinner viscosity is typically ideal.

The Infinity PUR WW60 is a replacement for Titebond WW60. It has a viscosity of 12,000 cps at 250°F that allows the adhesive to spread more quickly over surfaces and penetrate small gaps. On the other side, the Henkel Technomelt PUR 6202 has a viscosity of about 37,500 cps at 266°F is better suited to keep the adhesive in place without running or dripping.

Choosing the Right Applicator

Care should be taken when selecting the right applicator as they come in both high- and low-temperature versions. You want to select the applicator that matches the dispensing temperature of your PUR.

The adhesive should also not be exposed to air before application to prevent premature curing. For this reason, a standard adhesive applicator for traditional hot melt cannot be used. A specialty PUR applicator will keep the glue at optimum temperature and protect it from air exposure until it’s time for use.

The 3M Scotch-Weld Easy 250 PUR applicator is a popular choice for application at 250°F. It can hold this temperature for up to 16 hours at a time. Other adhesive applicators have both high- and low-temperature settings. The Infinity Bond Flex 50 PUR applicator, for example, can dispense at variable temperatures and has a digital temperature readout for precise measurement.

Need Help Finding the Right PUR Hot Melt?

There are some unique characteristics of PUR hot melts compared to other adhesives to help you narrow down your choice, but there are also numerous PUR products available. As a result, finding the right product for your job can be challenging. If you need more help, our adhesives experts are here to offer guidance and make recommendations. Just contact us today.