Whether discussing hot melt adhesive formulations or plain old white crafter's glue, the science of glue is a "tacky" situation. Invented around 1940, hot melt adhesives (HMA) are widely available for commercial, industrial and general use from a variety of manufacturers.

The sticky on hot melt adhesives

Based on thermoplastic polymers, the properties of hot melt adhesives allow them to melt when subjected to high temperatures and then return to a solid state when ambient temperature is reached. HMA products are extremely versatile, giving them a distinct advantage over traditional glue. They bond to just about anything, making them the obvious choice for use in a wide variety of industrial and commercial applications.

Most often you will see HMAs sold as hot melt glue sticks of varying length that are cylindrical in shape. The application is usually accomplished with the use of glue guns, but spraying or dipping are other methods employed when appropriate.

The specialized industrial glue gun holds the solid hot melt and melts it with an internal heating element. Operation of the gun is simple — either direct finger pressure or depression of a mechanical trigger mechanism forces the melted glue to squeeze out of the heated nozzle.

When first ejected, the glue is hot enough to burn skin on contact. For non-customized HMAs, it takes anywhere from seconds to minutes to completely solidify.

Uses for hot melt adhesives

HMAs are extensively used in common industries daily. You may not realize it, but there is a good chance that any assembled product you encounter has been at least partially constructed with the use of hot melt adhesives. The following are some recognizable examples:

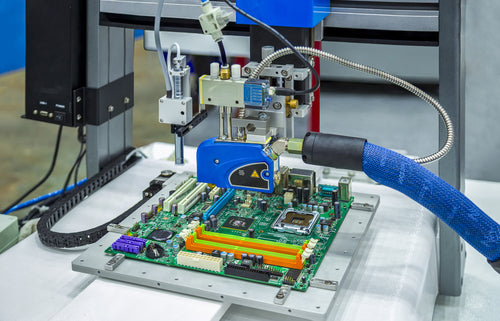

- Electronics: wire tacking and encapsulation

- Automobiles: seating assembly and interior trimming

- Packaging: pallet stabilization, wrapping, box and carton sealing and case closings

- Appliances: gasket installation and trim

- Furniture: panel and cabinet assembly

Why HMAs are better

Solvent-based adhesives fall far behind the advantages of HMAs. There is no need for curing, VOCs are eliminated or reduced, there are normally no specific regulations for disposal, and their shelf life is far superior.

Additionally, during the brief solidifying period, there is no loss of layer thickness. However, hot melt adhesives are not without their faults.

Without changing the formulation, some hot melt adhesives are sensitive to temperature, environmental changes and chemicals. In some circumstances, this can result in a complete loss of adhesion.

Depending on what the adhesives is to be used for, different strengths, set times, open times and viscosities may be required. Perhaps the biggest advantage to using hot melt adhesives is the ability to create a custom formulation that is perfectly suited to the task at hand.

Custom formulations

Modifying the base polymer and additives is the first step to creating a new custom hot melt adhesive formula. Different polymers have better results with specific materials and resins than others. Not only is it possible to change the structure of the adhesive, but it is also possible to add features such as low odor emittance, color, scent, enhanced flexibility and greater clarity with the addition of specialized tackifier resins. The basic process for creating a custom formulation works as follows:

- Polymers

The choice of polymer is made, usually from ethylene n-butyl acrylate, styrene block copolymers, ethylene-vinyl acetate, polyethylene, polypropylene, polyesters and polyamides, or polyolefins. The greater the percentage of polymer content, the higher the viscosity. Having a higher viscosity provides superior toughness and flexibility.

- Tackifying resins

The stickiness of your adhesive is referred to as "tack." The resin added into the polymer will determine how strong your tack is. If you prefer reduced tack, more resin is added into the mix.

The choice of resin relies on how compatible it is with your choice of polymer. The resins commonly used are C9, C5, pure aromatic monomers, rosin, hydrogenated rosin, rosin ester, terpene phenolics and hydrogenated hydrocarbon.

- Wax

The next step in the process is to add a wax. The primary purpose of using wax as an additive is to control the open time and set speed. Set speed is defined as the length of time it takes before a suitable bond strength is reached. Open time refers to the length of time it takes to make the bond, and this can vary from seconds to infinity.

Wax is also responsible for influencing adhesion in sub-ambient temperatures and resistance to heat. The more wax added into the mix, the stronger the bond, the higher the viscosity and the slower the set time. Wax is available as synthetic, natural and microcrystalline.

- Additional additives

The next two main ingredients are antioxidants and plasticizers. Plasticizers ensure the formulation has significant strength and flexibility. They are most often hydrocarbon oils with characteristics similar chemically to paraffin.

Antioxidants protect the glue in much the same way they protect the human body, by preventing degradation. BHT, phosphates, phenols, phosphites; aromatic amines are common antioxidants.

Other characteristics can be achieved by choosing to add ingredients such as flame retardants, fillers and biocides.

A final word

As you have learned, the combination possibilities for custom hot melt formulations are virtually unlimited. By choosing a partner who will work collaboratively with you to find and create the best product for the scope of your operation, product waste will decrease, production speed will increase, and there will be a reduction in operating costs. This puts money back where it should be: in your pocket!