Updated: September 10, 2024

Traditional Silicone Sealants

Silicone sealants are a liquid form of adhesive, although it looks, feels and acts like a gel. It is formed with a different type of chemical makeup compared to other, more organic polymer-based adhesives. Unlike those other adhesives, silicone is resistant to chemicals, moisture, and weathering. It also keeps elasticity and stability in both high- and low-temperature conditions.

Silicone sealants require curing, and typically, the temperature to cure the silicone can be anywhere between 50 and 100 degrees Fahrenheit. There also needs to be between 5 and 95 percent humidity for the silicone to properly cure. This process can take as little as 24 hours, but a thick application of sealant can sometimes take up to 48 hours to cure.

What Are High-Temperature Silicone Sealants?

High-temperature silicone sealants are a silicone adhesive sealant that can withstand temperatures as high as 600 degrees Fahrenheit. They are specially formulated to seal and encapsulate heating elements and industrial seals. They are also resistant to aging, vibrations, and shock.

![]()

High-Temperature Silicone Sealant Applications

When exposure to high temperatures is involved, a heat-resistant product is required in order for the seal to last. While heat resistance is such a specific property, applications for high-temperature sealants span a variety of uses and industries.

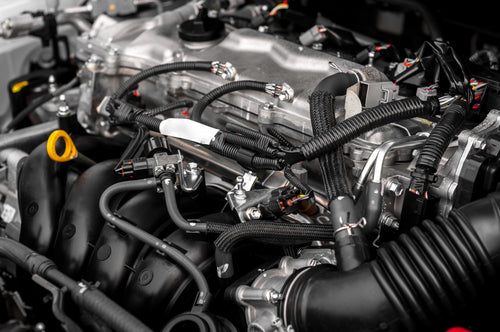

Automobiles

There are several applications for high-heat silicone sealants in the automotive industry because they are ideal for a hot engine. They are popular in areas where the joint or connection is exposed to high heat. For example, this high heat clear silicone is commonly used with valve covers, solenoid covers, axle housing, bearing cap seals, water and oil pump seals, and thermostat housings.

Industrial

Industrial silicones are used in various industries including plumbing, refrigeration, HVAC, commercial, and residential. High-temperature silicone sealants are particularly popular in industrial applications with pump and compressor gaskets, appliance door gaskets, humidifier gaskets, ductwork, insulating wire, and cable and furnace door gaskets.

One example is the industrial RTV sealant. This product offers long-term durability and is commonly used with formed-in-place gaskets for axle housings, differentials, junction box covers, and more.

Construction

Even though silicone isn’t a good substance for weight-bearing seals, it is still a powerful enough adhesive for many construction jobs. Applications for high-heat silicone in the construction industry may include sealing chimneys, stoves, fireplaces, and ventilation ducts.

Foodservice

High-temp silicone sealants with an NSF certification are used in foodservice applications or where food contact may occur, and high-temperature performance is needed. One example is American Sealants 600 heat resistant silicone. This type of high-temperature silicone sealant is formulated to perform at up to 600 degrees Fahrenheit during intermittent exposure and meets MIL-46106, Type 1, FDA, and USDA requirements.

How to Use High-Temperature Silicone Sealants

To get the best results, you should follow proper safety precautions and application instructions when using high-temperature and heat-resistant silicone sealants. To start, surfaces must be clean and dry before use.

Tool the sealant immediately after application. If you are using a cartridge, cut the nozzles at 45-degree angles to obtain the desired bead size. Use a caulking gun to apply the sealant by pushing it ahead of the nozzle. Tool the sealant immediately after the sealant is applied and aim to get the tooling done within a 5- to 10-minute window.

When bonding materials and sealants, apply a bead of adhesive to one surface and immediately combine the two parts together. Then apply pressure to ensure the surfaces are in full contact. The high-heat sealant should be dry to the touch within 30 minutes and fully cured within the first 24 hours.

Never mix the sealant with other chemicals, and always wear protective eyewear when applying. Also be careful not to allow the adhesive to touch your skin or to breathe in the fumes. After use, store the sealant in a cool, dry place between 40°F and 90°F. All the application equipment should be cleaned with warm water.

If you want to learn more about how to use high-temperature silicone sealants, we have adhesives experts ready to help. Just contact us today.